Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

A Method for Joining Two or more Dissimilar Metallic Components and a System thereof

Categories for this Invention

Technology: Joining two or more dissimilar metallic components;

Industry & Applications: Laser Industry, Fiber optics, Optical Transmission Industries.

Market: The global Filler metal market is projected to grow at a CAGR of 12% during the forecast period of 2024-2031.

Image Gallery

Problem Statement

- The technical problem discussed herein stating that how to reduce formation of intermetallic compounds around a welded portion in laser welding process.

- Such an objective technical problem is addressed by a method for joining two or more dissimilar metallic components.

Technology

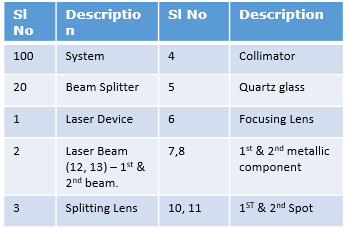

- Present invention describes a method for joining two or more dissimilar metallic components. (Refer Figs. 1,2 and 3)

- Said method comprises the steps of :

- This method splits the laser beam into the first beam & induced at the first spot is for pre-heating & the second beam induced at the second spot is for conduction welding, which lowers the interaction time of the laser beam with the overlapping portion of the metallic components & reduces formation of intermetallic compounds around the welded portion.

- The reduction of intermetallic compounds during welding improves the joint strength of the weld.

Key Features / Value Proposition

Technical Perspective:

Important Features:

- Facilitates the splitting of a high-power laser beam into at least two beams results in higher penetration depth compared to a single laser beam.

- Further, the metallic components joined by splitting the laser beam exhibits higher tensile shear strength of the joint.

Improved Performance:

- The focusing lens is positioned at about 50-100 mm from the first metallic component.

- (Refer fig.2)

- The distance between the first spot and the second spot is in the range of 0.5-1.5mm.

- The shielding gas may be supplied at a pressure of at least 0.5 bar and a flow rate of at least 25 l/min to avoid oxidation of molten weld pool during conduction welding.

Experimental Details:

The splitting of the laser beam by the beam splitter may improve the conduction of laser beam between steel & aluminum alloy.

Industrial Perspective:

- Universally applicable in the Optical fiber industries, Optical Transmission Industries.

Reference Details

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. SOUNDARAPANDIAN S

Prof. VIJAYARAGHAVAN L

Department of Mechanical Engineering.

Intellectual Property

IITM IDF Ref. 2001;

IN Patent No. 529025 (Granted)

Technology Readiness Level

TRL-3/4

Proof of Concept ready, tested & validated in Laboratory