Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Hard Particle Mixed Silver-Copper Based Brazing Filler Material for Joining Diamond to Steel Substrate

Categories for this Invention

Technology: Filler Material For Joining Diamond to Steel Substrate

Category: Assistive, Test Equipment & Design Manufacturing

Industry: Abrasive Manufacturers, cutting tool Manufacturers

Application: Machining operation

Market: The global market size estimated at USD 47.34 billion in 2024, and is expected to reach USD 66.83 billion by 2029, growing at a CAGR of greater than 5% during the forecast period

(2024-2029).

Problem Statement

- Diamond is used in super-abrasives for cutting/grinding tools like grinding wheels, dressing and truing tools, and honing discs.

- Electroplating or brazing technology is used to join diamond grits with a metal substrate.

- Brazing technology offers superior joint strength by developing a chemical bridge at the grit-alloy interface.

- Diamonds metastable at higher temperatures can deteriorate cutting edge sharpness and cause micro-cracks.

- Low melting temperatures and soft or ductile-based filler alloys are suggested to address these issues.

- Active Ag-based filler alloys have lower hardness value, leading to inferior abrasion resistance.

- Need for improved filler alloy formulations and silver-copper-based filler material for diamond to steel substrates.

Technology

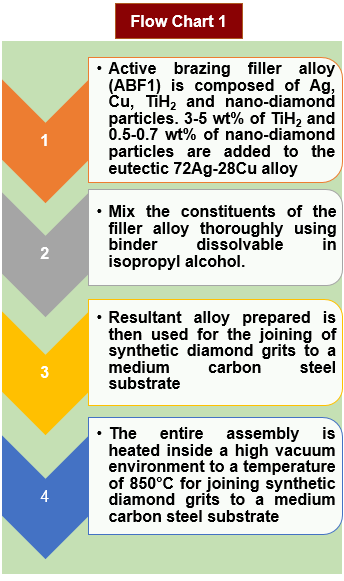

Formulation of active brazing filler alloy (ABF1)

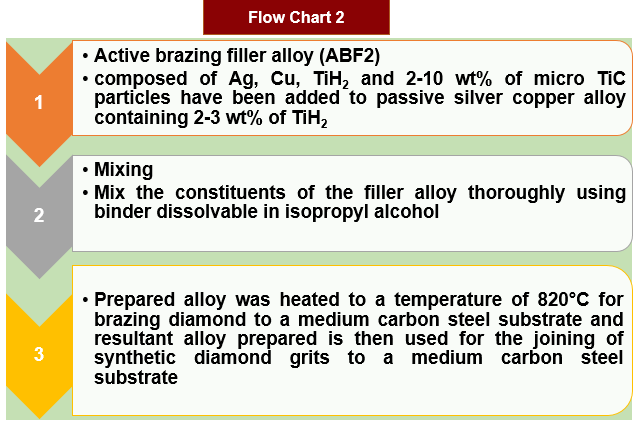

Formulation of active brazing filler alloy (ABF2)

Key Features / Value Proposition

Filler Material

Vacuum Level

- The filler material wherein the vacuum level maintained during the brazing process was in the range of 10-6 to 10-7 mbar.

Heating Temperature

- The filler material wherein the entire assembly is heated inside a high vacuum environment to a temperature of 850 °C.

Wear Resistance

- The filler material wherein the nano-diamond added filler demonstrates wear resistance property by 50-60% and the brazed joint strength is reduced by 30-40%

Abrasion resisitance

- Filler alloy exhibited a significant increase in the abrasion resistance property by about 73-91% and the brazed joint strength was reduced by an extent of 20-30%

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. Amitava Ghosh

Department of Mechanical Engineering

Intellectual Property

IITM IDF Ref. 1707

Patent No: IN 461065

Technology Readiness Level

TRL- 4

Experimentally validated in Lab