Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

A Turning Cutter Design for Enhancing the Efficiency of Cutting Processes

Categories for this Invention

Technology: Turning cutting tool design

Category: Assistive, Test Equipment & Design Manufacturing

Industry: Cutting tool design & Manufacturing Industry

Application: Machining operations.

Market: The global market size was estimated to be worth USD 25200 million in 2022 and is forecast to a readjusted size of USD 35540 million by 2028 with a CAGR of 5.9% during the forecast period 2022-2028

Problem Statement

- Parasitic mechanisms like chatter, tool wear, and plowing can hinder metal cutting processes by generating higher forces and energy consumption.

- These mechanisms have been studied individually, but collectively affect the cutting process.

- Solutions often involve using auxiliary components or mathematical calculations to determine favorable conditions for cutting, which are expensive and cumbersome.

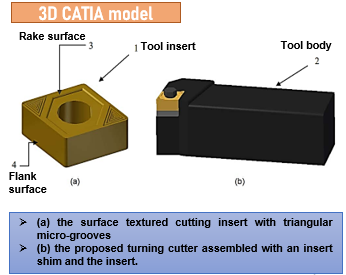

- The inventions describe composite micro-texture super hard tools and semi-finish machining indexable turning tool blades for nickel-based superalloy semi-finish machining, featuring a tool body and micro-texture tool bit and the art of tool and cutter designs is intricate and complex.

- There is a need for a simple, benign solution based on metal cutting physics.

Technology

Key Features / Value Proposition

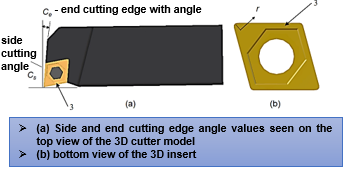

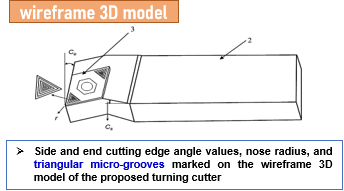

Nose Radius (r) = 0.1 to 0.2 mm:

- Sharp tool mitigates chatter by alleviating cross-coupling effect

- Reduced tool strength due to sharp nose is compensated by thicker insert body

- Increased surface roughness controlled by MC effect, low Ce and moderate Cs

Side Cutting Edge Angle (Cs) = 20 °

- Chatter control by nullifying interference effect and controlling regenerative effect

- Improved tool life owing to cutting forces being distributed onto a larger area

- Improved surface quality through reduced chatter and vibration.

End Cutting Edge Angle (Ce) = 10°

- Back forces kept in check to avoid chatter

- Sufficient clearance between tool and workpiece reduces tool wear

- Low Ce is congenial for a better machined surface

Surface Texturing

- Reduced cutting forces and cutting temperature due to smaller tool-chip contact contributes to chatter control

- Improved tool life due to reduced friction and improved heat dissipation by solid lubricant

- Negative impact on surface quality compensated by proposed tool geometry features of Cs and Ce + MC effect

Mechanochemical Effect

- Sinuous flow, a material deformation mode, generates large forces and thick chips.

- Prestraining the annealed work material can reduce strain and cutting forces by 70%.

- Applying a Dykem ink layer can suppress sinuous flow, reducing cutting forces and improving surface quality.

Advantages

- A cutter with lower cutting forces and energy consumption.

- Alleviate parasitic mechanisms like chatter, tool wear, and plowing.

- Having sustainability in manufacturing.

- Novel Turning Cutter Tool Design.

- Features smaller nose radius, designated cutting edge angles, and surface texture on insert rake face.

- Incorporates geometry features and mechanochemical effect to reduce cutting forces and energy.

- Improved surface quality, increases tool life, and increases throughput.

- Suitable for multipoint milling and precision cutters, facilitating sustainable machining operations.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. Balakrishna C Rao

Department of Engineering Design

Intellectual Property

IITM IDF Ref. 2345

Patent No: IN 540842

Technology Readiness Level

TRL- 4

Experimentally validated in Lab