Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Superplasticizer and Workabilty Retention Agent for Concrete and Mortar with Limestone Calcined Clay Cement

Technology Category/Market

Category-Civil Infrastructures & Structural Engineering

Industry Classification:

NIC (2008)- 23942– Manufacture of portland cement, aluminous cement, slag cement and similar hydraulic cement; 2395- Manufacture of articles of concrete, cement and plaster

Applications:

Manufacture of Cement, Ready-mix concrete and Cement additives

Market report:

The Global limestone calcined clay cement market, was valued at USD 722.4 million in 2023, and is projected to grow to USD 1,167.6 million by 2031 at a CAGR of 6.2%

Image Gallery

Problem Statement

- Limestone calcined clay cement (LC3) is composed of ordinary Portland cement, calcined clay, and limestone and is prepared as per IS:18189-2023.

- Concrete is prepared by mixing LC3, aggregates, and water. However, concrete and mortar system made with LC3 loses workability rapidly within the first few hours of mixing.

- Concrete containing conventional superplasticizers exhibit a reduction in the slump value by about 40 to 60% within the first 1 to 2 hours from mixing for a normal LC3.

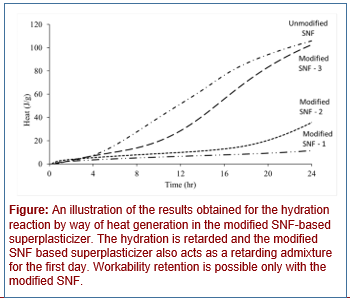

- Sulphonated Naphthalene formaldehyde (SNF) used to reduce the water demand of the concrete and act as a superplasticizer for normal concrete is not sufficiently effective for LC3-based concrete.

- There is a need for a modified SNF-based superplasticizer for LC3-based concrete and mortar systems that prevents reduction in slump value for a sufficient period of time by retarding the hydration.

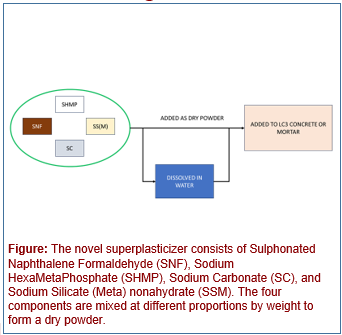

Technology

- The novel superplasticizer consists of sulphonated naphthalene formaldehyde (SNF), sodium hexametaphosphate (SHMP), sodium carbonate (SC), and sodium silicate (meta) nonahydrate (SSM). The four components are mixed at different proportions by weight to form a dry powder.

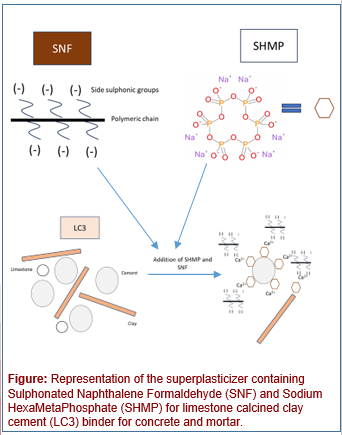

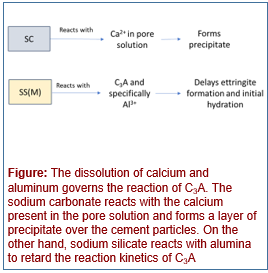

- The sodium hexametaphosphate gets adsorbed on the surface of calcined clay (preferably Al3+ sites) and cement particles, altering the electronegativity of the surface.

- Further, the calcium ions get attached to the sodium hexametaphosphate, creating a Ca-Sodium hexametaphosphate (Ca-SHMP) complex. The side sulphonic groups of SNF get attracted toward the positive calcium ions in the Ca-SHMP complex.

- The dissolution of calcium ions and alumina ions controls the initial hydration reaction and the workability loss. The LC3 cement system has higher C3A content, which leads to faster hydration and ettringite formation, leading to workability loss within an hour of mixing.

Key Features/Value Proposition

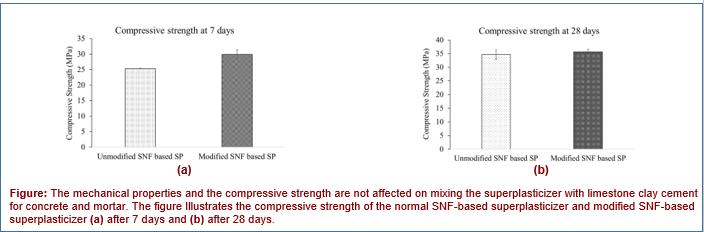

- The workability loss is reduced to less than 8% for water to binder ratios 0.35 and 0.40 on adding the superplasticizer.

- The mechanical properties and the compressive strength are not affected on mixing the superplasticizer with limestone clay cement for concrete and mortar.

- Compared to conventional cement, LC3 is cost-effective as it is made using limestone and low-grade clays which are available in abundant quantities. Further, LC3 helps in the reduction Carbon dioxide emissions by up to 40%.

- The mixture is usable in both dry powder form and water soluble form. the composition is configured for retardation of ettringite formation, leading to higher workability retention of limestone calcined clay cement concrete and mortar.

- The workability drop in terms of slump and flow value on adding the superplasticizer is limited to 5 to 10% within the first 1 to 2 hours of mixing.

Questions about this Technology?

Contact for Licensing

Research Lab

Prof. Manu Santhanam

Department of Civil Engineering

Intellectual Property

- IITM IDF Ref 2809

- IN : 551460- Patent Granted

Technology Readiness Level

TRL 4

Technology Validated in Lab