Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Plant Extract Loaded Titanium Dioxide Nanotube based Drug Delivery System

Categories for this Invention

Category: Drugs and Pharmaceutical

Industry: Pharmaceutical

Application: Bone healing in mammals

Market: The global drugs and pharmaceutical market size was valued at USD 209.85 billion in 2019 and is poised to grow from USD 222.4 billion in 2023 to USD 352.98 billion by 2031, growing at a CAGR of 5.9% in the forecast period (2024-2031).

Image Gallery

Problem Statement

- Plant based extracts are rich in natural pharmaceutically active molecules. Techniques and methods for screening plant-based phytomolecules are increasingly becoming popular in recent times.

- The recent advancements in the field of computer based molecular design, combinatorial chemistry and synthetic chemistry has led to development of biomimicking of the plant-based compounds for pharmaceutical effects. But the techniques are not equally promising compared to the natural plant extract phytomolecules.

- The existing systems are unable to render an efficient drug delivery mechanism using plant extracts such as Blepharis maderaspatensis.

- Also, the plant-based molecules suffer from low bioavailability when introduced into the physiological environment.

- Elimination of the active constituent occurs by the action of pH, enzymes within the conventional route of passage of drugs.

- Based on the foregoing a need therefore exists for an improved plant extract-based drug delivery system and method for enhanced and targeted bone healing.

Technology

- A plant extract (Blepharis maderaspatensis) or ‘Elumpuotti’ loaded titanium dioxide (TiO2) nanotube based drug delivery system, comprising:

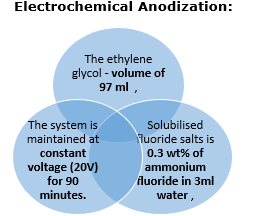

- Titania nanotubes (TNTs) formed using two electrodes electrochemical anodization setup, wherein titanium is set as anode and platinum is used as cathode;

- Plant extract loaded onto the titania nanotubes (TNTs),wherein the titania nanotubes (TNTs) are cleaned in 70% Iso-propanol and acetone and are immersed in deionised water and subjected to UV treatment for 20 minutes for sterilizing before loading the plant extract.

- A biopolymer coating on the surface of the plant extract loaded titania nanotubes (TNTs) to achieve controlled drug release, wherein the plant extract comprises Blepharis maderaspatensis that is loaded onto the titania nanotubes (TNTs) using dip coating approach, and wherein the biopolymer is collagen.

- The extraction of the plant material is done by cold maceration using hexane, dichloromethane (DCM), methanol and water successively for 24h on the powdered plant leaves wherein the plant material is soaked in the solvent and stoppered to prevent external reaction.

- Elimination of the active constituent occurs by the action of pH, enzymes within the conventional route of passage of drugs.

Key Features / Value Proposition

- Both Hydrophobic and Hydrophilic therapeutic molecules from the plant leaves are used.

- Hank’s solution is used for study the drug release and osseo integration property.

- Two electrodes for electrochemical anodization titanium as anode and platinum as cathode are used in formation of drugs.

- Field Emission Scanning Electron Microscopy (FESEM) were used to procure surface images.

- MG 63 cells (osteosarcoma) are seeded on the surface of the drug loaded TNTs.

- For Cytotoxicity, MTT (3- [4,5-dimethylthiozol-2-yl]- 2,5 diphenyl tetrazolium bromide) (Analytical grade, HiMedia) assay were used.

- Enhanced for localized bone healing in mammalian.

- High Controlled Drug Release due to biopolymer coating.

- No toxicity in the existing cells and cost effective.

- Form III Acknowledged from National Biodiversity Authority (NBA) for Plant extract uses.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. Dr.TUHIN SUBHRA SANTRA

Ms. KEERTHIGA G ,Mr. L. MOHAN

Department Of Engineering Design

Intellectual Property

IITM IDF Ref. 2181

Patent No: IN 530839;

Technology Readiness Level

TRL-4

Experimentally validated in Lab;