Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

An Air Handling System for Production of Water from Atmospheric Air and a Method thereof

Categories for this Invention

Category- Environmental Engineering

Industry Classification:

- NIC (2008)- 3600- Water collection, treatment and supply; 28195 Manufacture of filtering and purifying machinery or apparatus for liquids and gases; 28192– Manufacture of air-conditioning machines

- Applications: Drinking water dispensers, Water efficiency enhancing technologies, Water purifiers, Dehumidifiers.

Market drivers:

The global water purifier market size is projected to grow from $33.65 billion in 2023 to $54.48 billion by 2030, at a CAGR of 7.6%

Image Gallery

Problem Statement

- The rise of carbon dioxide levels in the atmosphere may be controlled by developing processes that convert CO2 present in industrial flue gases into value added products such as formic acid.

- Existing electrochemical processes for removal of CO2 from flue gases do not take into consideration the presence of other pollutants such as SOx and NOx that may affect the conversion process.

- There is a need for a catalyst for the electrolytic conversion of CO2 to formic acid even in the presence of impurities such as SOx and NOx

Technology

The air handling system is a dual system both for the production of water from atmospheric air and as well for the air conditioning system.

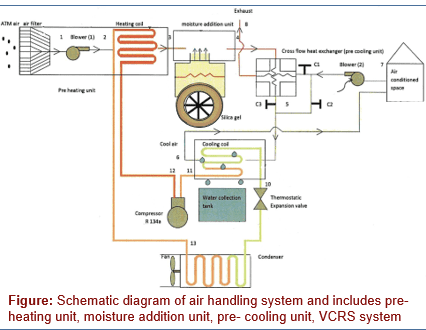

The air handling system is a dual system both for the production of water from atmospheric air and as well for the air conditioning system.- The invention consists of an air handling system for production of water from atmospheric air consisting of pre-heating unit, moisture addition unit, cross flow heat exchanger, cooling units, compressor and condenser.

- The water production was between 600 -800 liters per day when the temperature is in range 35 ° C to 40° C, the RH is in the range 50-90%. Necessary minerals can be added to the purified water as required.

- If water production is not required or sufficient water is already produced then the duct closers can be used to enable the system to work as a normal air conditioner and provide 5 ton cooling effect.

- Regions with high temperature and relative humidity enable higher water production rates, whereas in low temperature and humidity regions the both the water produced and power consumed is low.

Key Features / Value Proposition

- This system can provide clean drinking water irrespective of weather conditions. Providing decentralized water supply even in remote and disaster affected regions

- Water produced by this system will be the purest form containing only 6-20 ppm TDS level, Whereas, purified water from conventional purifiers contains a TDS of 100-150 ppm

- Water production cost will be approx. 0.2-0.3 kWh/litre which will be around 1.5-2.5 Rs/litre. Whereas, conventional bottled mineral water retails at 20 Rs/litre.

- This system will provide co-produces air conditioning and drinking water enabling a cost effective solution with very low maintenance.

- The system has high durability and reliability while wasting less water compared to conventional RO water purification systems.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. K Srinivas Reddy

Department of Mechanical Engineering

Intellectual Property

- IITM IDF Ref.1855

- IN 490444 Patent Granted

Technology Readiness Level

TRL 2

Technology concept formulated