Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Rotary Kiln Incinerator for Generating Energy from Municipal Solid Waste

Categories for this Invention

Category- Environmental Engineering

Industry Classification:

- NIC (2008)- 382- Waste treatment and disposal; 251- Manufacture of structural metal products, tanks, reservoirs and steam generators.

- NAICS (2022)- 562213- Solid Waste Combustors and Incinerators

- Applications: Sustainable Municipal Solid Waste incinerators.

Market drivers:

Global waste management market is estimated at USD 1219.6 Billion in 2024 and is projected to grow to USD 1598.1 Billion by 2029 with a CAGR of 5.6%

Image Gallery

Problem Statement

- Disposal of Municipal Solid Wastes (MSW) in landfills is harmful as there is an increase in soil and ground water pollution in urban areas.

- Conventional approaches of MSW disposal using incineration pose several challenges in handling waste. As MSW has very low calorific value fuel, sustaining the flame for combustion is difficult without use of external fuel sources.

- Drying of MSW (before its combustion) consumes significant amount of energy. Whereas, release of harmful pollutants is a matter of concern.

- There is a need for an improved rotary kiln for treatment of MSW that sustains combustion for incineration while recovering heat energy and treating emissions.

Technology

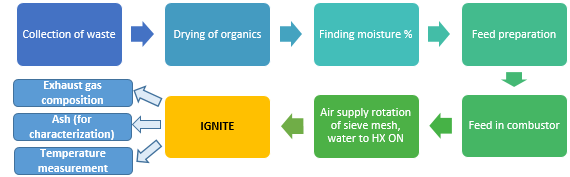

- The kiln used for the basic construction of boiler is made from aluminum. The diameter and length of the incinerator rated at 20 kWth are 450 mm and 650 mm respectively.

- The sieve mesh of 400 mm length and 400 mm diameter is fitted inside the rotary kiln. The sieve mesh has square opening s of 1 cm x 1 cm for effective combustion of the unsegregated feedstock. This helps in removing ash from the unburnt MSW fuel and helps in effective combustion. The sieve mesh was rotated using a 12 V DC motor, which was connected to it through a gear arrangement.

- The kiln was insulated and inclined.to automatically push the feed into the furnace. A cross-flow type shell and tube heat exchanger is used to recover heat

Key Features / Value Proposition

- Experiments were carried out using MSW mixtures with low calorific values in the range of (22.9-29.8 MJ/Kg). The invented combustor is capable of handling lower calorific value MSW mixtures when compared to conventional incinerators.

- The composition of CO, C02, S02, NOx, TOC, HCI , HF, particulates were within limits. Maximum temperature of the exhaust gases was within 600 °C, and average temperature was 230-280 °C. This resulted in NOx levels in the exhaust within the allowed limits as per 2016 MSW boiler emission norms.

- The combustor was successfully tested using industrial waste and packaging-plastic waste at BHEL, Trichy (500 kWth) and IIT Madras (100 kWth) respectively to generate steam for power production.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. Vinu R

Department of Chemical Engineering

Prof. Chakravarthy S R

Department of Aerospace Engineering

Prof. Prasad B V S S S

Department of Mechanical Engineering

Prof. Sundararajan

Department of Mechanical Engineering

Intellectual Property

- IITM IDF Ref. 2026

- IN 517599 Patent Granted

- PCT Publication no: WO2022029802

Technology Readiness Level

TRL 4

Technology Validated in Lab