Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Apparatus for carrying out continuous passive mixing and/or chemical reactions for multiphase/multispecies fluids.

Categories for this Invention

Passive mixing,

multiphase fluids,

multispecies fluids,

Targeted Industries

Watermarking IP design,

Electronic circuits

Image Gallery

Questions about this Technology?

Applications

Passive mixing multiphase fluids, chemical and petroleum, biotech and pharma fluid mixing applications

Problem Addressed

Existing passive mixers require longer length of the channels for achieving mixing such as by creeping structures, folding structures, serpentine channels, etc. Limited by requirement of specialized equipment increasing the equipment and maintenance costs, inability to be easily scaled up and down, longer length, lack of integration, inability to prevent defects or incomplete mixing through formation of secondary vortices or dead zones. An apparatus for mixing fluids in a cost effective manner thereby eliminating the aforementioned problems is needed.

Abstract

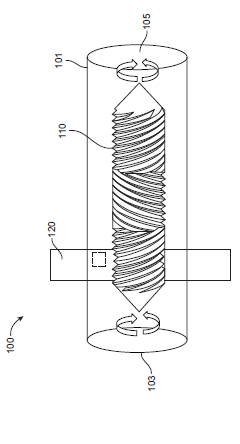

An apparatus for passive mixing of multiphase fluids is provided. The apparatus includes an outer static chamber with a fluid inlet and outlet, and housing at least one mixing element placed concentric to the static chamber. The mixing elements include conical ends and threaded surfaces with thread sets oriented so as to promote mixing. The mixing elements are held in position by a connecting member. The primary fluids enter the chamber through the fluid inlet and passes through a clearance region between the chamber and the mixing element. The surfaces of the static chamber and mixing element may have different wetting capabilities. The connecting member may supply a secondary fluid and also include a temperature control mechanism. The apparatus prevents formation of secondary vortices during operation allowing thoroughly mixed fluids to exit the chamber. Modification of roughness and wetting characteristics of the surfaces may further enhance/control the mixing capabilities.

Advantages

1. The apparatus has better control over the residence time distribution,

2. It is robust, economical and easily scaled up or scaled down.

3. Less power requirement