Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Method for Generation of Nanoparticles using Advanced Mechanical Micro-machining Technique

Categories for this Invention

Technology: Method for Generation of Nanoparticles

Category: Micro & Nano Technologies

Industry: Manufacturing /chemical, Automotive, Biomedical

Application: Micro machining, Production of Nanoparticles

Market: The global market size is estimated to grow from USD 5.1 billion in 2023 to USD 15.1 billion by 2035, representing a CAGR of 9.4% during the forecast period 2023-2035

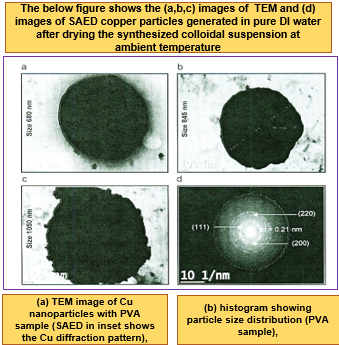

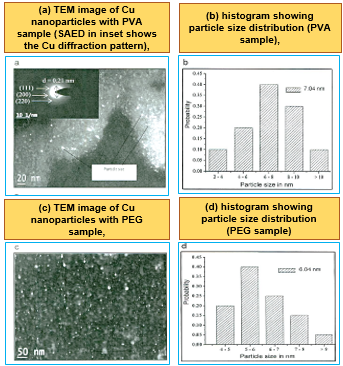

Image Gallery

Problem Statement

- Micromachining is essential for advanced materials in aerospace, defense, and automotive industries.

- Electrical Discharge Machining (EDM) is a cost-effective method for machining hard and brittle materials, but tool wear is a major issue.

- Nanotechnology is increasingly important in producing nanoparticles with novel properties, which are used in various fields.

- Studies on nanoparticle properties using micro-EDM have shown improvements in machining stability, efficiency, and quality.

- Micro-EDM removes material through melting and evaporation through repetitive spark discharges.

- There is a need for collection, reveal, control, and testing of debris structure, highlighting potential use in industrial or medical applications.

Technology

Key Features / Value Proposition

Nanoparticle Generation System

- Micro-Electrical Discharge Machining System

Method for Tool Vertical Displacement

- Non-contact mechanical method

Controlled by an amplified piezoactuator with a maximum Displacement

- 400 µm at 150 V.

Supply voltage

- Ranges from 10-120 V.

Pulse duration

- Adjustable at any time.

Pulse frequency

- Ranges from 1kHz -5 kHz.

Duty cycle

- Ranges from 5% – 50%.

Pulse duration

- Less than 100 μs.

Size

- Nanoparticles generated in size less than

100 nm with high yield

Base fluid for colloidal suspension

- Uses DI water

Stabilizer

- Uses organic/inorganic stabilizer for suitable nanoparticle size and shape.

- Technique also applicable for hybrid nano particles.

- Nanoparticles generated from conducting, semiconducting, and electrically conducting materials.

- Simple, straightforward, and economical process based on thermoelectric energy between tool and workpiece electrodes.

- Utilizes a custom-made setup with a piezoactuated tool feed system.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. Somashekhar S Hiremath

Department of Mechanical Engineering

Intellectual Property

- IITM IDF Ref. 1209

- Patent No: IN 347900

Technology Readiness Level

TRL- 3

Experimental Proof of concept;