Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Non-destructive Evaluation Employing Mode-confined Uni-dimensional Guided Waves – System, Apparatus And Methods Therefor

Categories for this Invention

Category-Non-Destructive Testing Methods & Equipment (NDT/NDE)

Industry Classification:

- NIC (2008)- 26511 Manufacture of physical properties testing and inspection equipment

- NAICS (2022)- 334519 Other Measuring and Controlling Device Manufacturing (Physical properties testing and inspection equipment); 7120 Technical testing and analysis

- Applications: Testing and repair of aerospace composites, aircraft repair and maintenance

Market report:

Global NDT In The Aerospace And Defense Market size is estimated at USD 9.11 billion in 2024, and is expected to reach USD 18.92 billion by 2029, growing at a CAGR of 15.74%

Image Gallery

Problem Statement

- The use of stiffened composites is common in aerospace box-like components and provides the additional stiffness required in structures such as aero foils, fuselage, wing box and tail section etc.

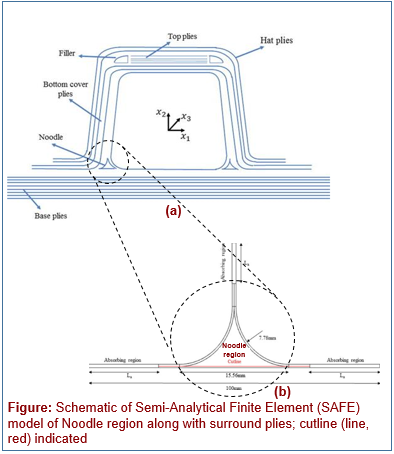

- However manufacturing considerations require conformal deltoid radius fillers (noodle) with localized bar-like geometry in the interface between the skin and stiffeners in T-joints. These noodles are at an increased risk of delamination and hence need to be periodically assessed.

- Conventional NDE tend to be generic and require point-by-point scanning of the whole structure which is tedious and time consuming while not reaching interior regions of such joints.

- There is a need for a cost-effective method of rapid scanning of the whole composite using a single transducer based on a recently discovered phenomenon of mode confinement in composite noodle regions.

Technology

- Noodle regions are bar/rod-like (typical of trigonal type, but sometimes of circular cross-section), and consist of filler materials different from the parent composite Materials. Often such Noodle sections are at an increased likelihood of delamination or separation from the stiffened component, and periodic assessment of their condition is critical

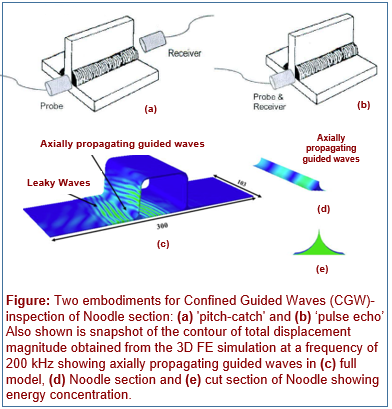

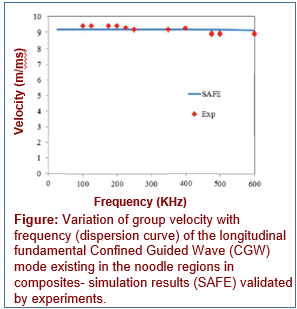

- The Noodle system can support a number of CGW modes, which have different modal structure and wave speed depending on the frequency of operation. Once generated in the Noodle system, CGW modes can travel long distances, typically in the range of several meters without much attenuation

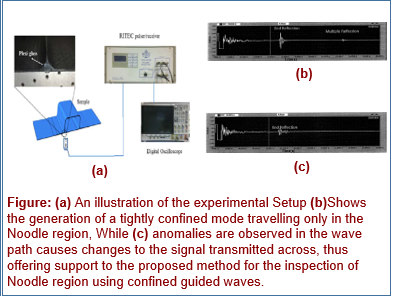

- Upon encountering anomalous or defective features, will scatter waves back and onward. Such scattered waves contain a signature of the defective feature, and once detected, can provide information on their location and extent. .

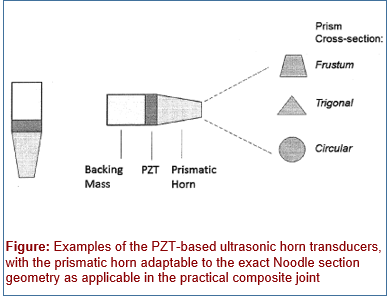

- Specialized PZT based horn transducers have been developed to permit a complete characterization of the Noodle sections in composite joints from a single access point, and provide information on severe failure zones.

- The said transducers in this prototype are designed to operate in (but are not limited to) the low-frequency guided wave regime of 50 kHz – 4 Mhz and as such are generic within this frequency range.

- The signals were sent to a 100 kHz wide-band piezoelectric transducer which was acoustically coupled to the test specimen. During the experiment it was observed the generation of a tightly confined mode travelling only in the Noodle region.

Key Features / Value Proposition

- The technology is developed based on a discovery made by the inventors about novel Confined Guided Wave (CGW) in noodle regions.

- The invention provides an NDE with simple hardware that enables rapid scan of hard to reach regions such as noodle regions in a composite. Whereas conventional methods require point-by-point scanning of the whole structure thus making the process tedious and time consuming.

- The invention provides for a methodology based on the phenomenon of localized or confined (1-Dimensional) ultrasonic guided waves. Whereas conventional methods involve ultrasonic guided waves propagating in 2-Dimensions, thus the range and resolution achievable by such guided waves is highly dependent on distance to and the size of features of interest.

- Specialized PZT-based ultrasonic horn transducers have for the first time been developed for the generation and reception of CGW modes in composite Noodle systems. These horn transducers are tailored to the specific geometry of noodle region to be inspected, and are highly modular as opposed to conventional integrated horn solutions cannot generate such specific CGW modes.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. Prabhu Rajagopal

Department of Mechanical Engineering

Prof. Krishnan Balasubramaniam

Department of Mechanical Engineering

Intellectual Property

- IITM IDF Ref.1206

- IN 337572 Patent Granted

Technology Readiness Level

TRL 5

Technology Validated in Relevant environment

Related posts:

- IDF No 2124 Method and System for Generating Time-efficient Synthetic Non-Destructive Testing Data

- IDF No 861 A Method for Non-destructive Structural Health Monitoring

- IDF No 1729 System and Method for Ultrasonic Inspection of Curved Surfaces

- IDF No 1925 Staggered Magnet Array (SMA) Based Electromagnetic Acoustic Transducer (EMAT)