Industrial Consultancy & Sponsored Research (IC&SR) , IIT Madras

Titania-Silica Coating for (i) Protection of Metal Surfaces and (ii) Ophthalmic Coating Applications

Categories for this Invention

Technology: Titania-silica Coating;

Industry & Application: Silver Industry, Jewelry, Ophthalmic lenses

Market: The global silica coating market is projected to grow at a CAGR of 9.9% during 2024-2030.

Image Gallery

Problem Statement

- Protection of metal surfaces, particularly the optical shine of silver, against the environment is a challenge. Daily usage of silver articles (mainly, the cutlery, crockery and the tableware) needs special protection against mechanical abrasion. The coatings technology imposes additional challenge of complex shapes of the silver / metal articles.

- When high refractive index ophthalmic lenses are to be used, one needs an anti-reflection coatings which should have high and uniform (over the entire visible wavelength range) refractive index and abrasive resistance coatings compatible with lens coating technology.

- Hence, there is a need to address the issues.

Technology

- Present invention describes a method of preparing a coating material which is the mixed metal oxides of Titanium & Silicon prepared at 300K (Room temperature).

- The solution can be used for anti-tarnish and protective coatings on metal surfaces.

The basic method comprising the following step as illustrated in the smart chart:

Basic Process Flow Diagram:

- The titania-silica based coating material can be prepared at room temperature and can be deposited on any complex shapes and has anti-reflection and mechanical abrasion resistance coating on optical materials.

- Said titania-silica based coating material can be used as protective coating layer for silver metal & silver alloys.

- Furthermore, the claimed invention deals with any wavelength of the anti-reflection application & the refractive index of the present invention is a key outcome which is depicted in Fig. 1.

- The titania-silica based coating can be used as anti-reflection and mechanical abrasion resistance coatings on optic lenses including plastic lenses.

- The protective coatings are deposited by dip coating technique of desired thickness.

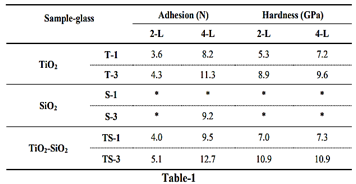

- Table 1 provides the summary of adhesion & hardness results for TiO2, SiO2, & TiO2+SiO2 thin films on glass as 2 and 4 layers.

Test Results

Key Features / Value Proposition

Technical Perspective:

- The sol-gel technique to prepare the titania-silica thin films is easy, cost-effective & can be scaled up to the Industrial level.

- The optical properties of the sol-gel derived titania-silica is unique.

- Dip coating technique of desired thickness.

- For significant enhancement in the coating performance, the coatings can be cured at 200oC for about 20 minutes either in inert atmosphere or in low vacuum~ 10-2 mBar.

- Claimed Sol gel derived titania-silica coating specifically used to protect silver surfaces from sulfide & sulfate.

- The preparation parameters including gelling time, pH of the sol, temperature, sol concentrations determine the properties of the sol and consequently, each sol has a specific application.

Industry Perspective:

- Claimed invention has multi-utility in a wide range of surface protection of metal/metal alloy & optical coating applications where one needs optical refractive index matching and abrasion resistance.

Questions about this Technology?

Contact For Licensing

sm-marketing@imail.iitm.ac.in

ipoffice2@iitm.ac.in

Research Lab

Prof. SUBRAHMANYAM A

Department of Physics

Intellectual Property

IITM IDF Ref. 1744

IN Patent No: 526956

Technology Readiness Level

TRL-4

Proof of Concept ready, tested in lab.